As part of projects focused on improving and modernizing industrial infrastructure, INGECID executed the comprehensive digitalization of an automotive production line. The work involved the precise capture of the existing environment through point clouds—covering machinery, components, and production areas—to generate a digital model that enables more efficient management of the industrial facility.

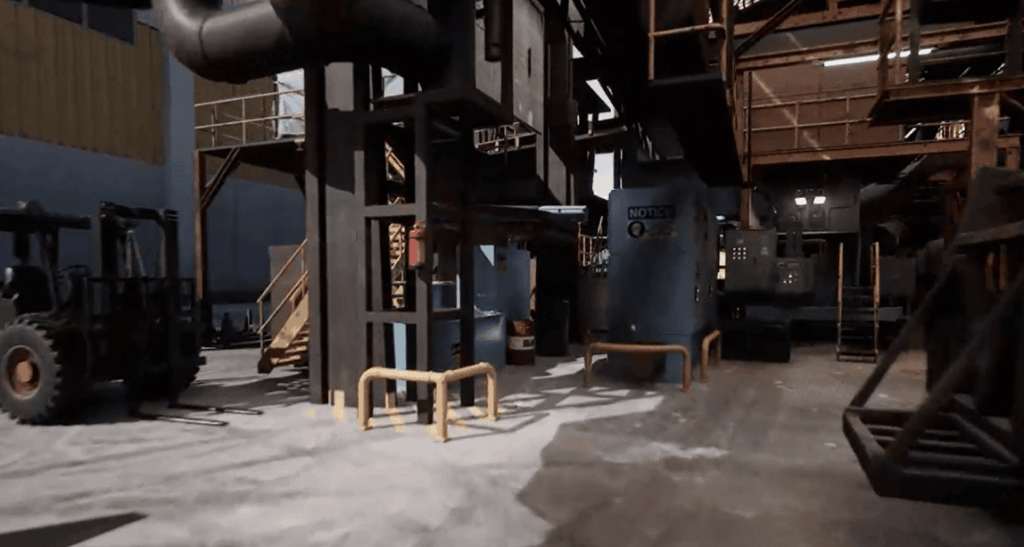

The project included the development of BIM models for the existing conditions, enabling spatial and technical analysis for future equipment and production line replacements. This optimized planning and minimized disruption to daily operations. Additionally, advanced visual content—such as renders and virtual reality environments—was created to simulate interventions, validate design alternatives, and support collaborative strategic decision-making.

This project represented a major step toward a fully digital production infrastructure, integrating BIM methodology, immersive environments, and analytical tools that enhance sustainability, efficiency, and adaptability in next-generation industrial facilities.